Peb paub tias peb tsuas yog vam meej yog tias peb tuaj yeem lav peb cov nqi sib tw thiab qhov zoo tib lub sijhawm rau eMG1 lub tshuab foob rau kev lag luam marine rau lub twj tso kua dej, kev ua siab dawb siab zoo thiab lub zog, ib txwm tswj hwm qhov zoo tshaj plaws, txais tos rau peb lub Hoobkas rau kev mus rau thiab kev qhia thiab kev lag luam me.

Peb paub tias peb tsuas vam meej yog tias peb tuaj yeem lav peb qhov kev sib tw nqi thiab qhov zoo tib lub sijhawm rau, Peb ib txwm tsim cov thev naus laus zis tshiab los ua kom yooj yim rau kev tsim khoom, thiab muab cov khoom lag luam nrog cov nqi sib tw thiab zoo! Kev txaus siab ntawm cov neeg siv khoom yog peb qhov tseem ceeb! Koj tuaj yeem qhia rau peb paub koj lub tswv yim los tsim cov qauv tsim tshwj xeeb rau koj tus qauv kom tiv thaiv ntau qhov zoo sib xws hauv kev ua lag luam! Peb yuav muab peb cov kev pabcuam zoo tshaj plaws rau koj kom txaus siab rau txhua yam koj xav tau! Nco ntsoov hu rau peb tam sim ntawd!

Cov yam ntxwv

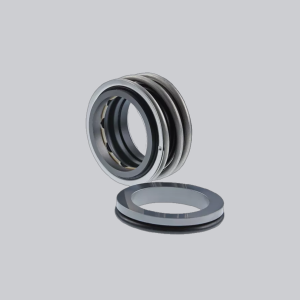

Rau cov shafts yooj yim

Ib qho thiab ob lub foob

Elastomer bellows tig

Sib npaug

Ywj siab ntawm kev coj ntawm kev sim tig

Cov txiaj ntsig

- 100% sib xws nrogMG1

- Qhov me me ntawm lub bellows support (dbmin) ua rau muaj kev txhawb nqa ncaj qha rau lub nplhaib tuav, lossis cov nplhaib spacer me dua

- Qhov zoo tshaj plaws ntawm kev sib dhos los ntawm kev ntxuav tus kheej ntawm lub disk / ncej

- Txhim kho qhov chaw nruab nrab thoob plaws tag nrho cov kev ua haujlwm siab

- Tsis muaj torsion ntawm lub bellows

- Kev tiv thaiv ntawm lub ncej hla tag nrho qhov ntev ntawm lub foob

- Kev tiv thaiv ntawm lub ntsej muag foob thaum lub sijhawm teeb tsa vim yog kev tsim tshwj xeeb ntawm lub bellows

- Tsis rhiab rau qhov deflections ntawm tus ncej vim muaj peev xwm txav mus los axial loj

- Haum rau cov ntawv thov qis qis sterile

Cov ntawv thov pom zoo

- Kev muab dej tshiab

- Kev pabcuam kev tsim kho vaj tse

- Kev siv tshuab dej khib nyiab

- Kev siv tshuab ua zaub mov

- Kev tsim cov suab thaj

- Kev lag luam pulp thiab ntawv

- Kev lag luam roj

- Kev lag luam roj av

- Kev lag luam tshuaj lom neeg

- Dej, dej khib nyiab, slurries

(khoom khov txog li 5% los ntawm qhov hnyav) - Pulp (txog li 4% ntawm cov rog)

- Cov roj hmab

- Cov khoom noj mis nyuj, dej haus

- Cov tshuaj sulfide slurries

- Cov tshuaj lom neeg

- Cov roj

- Cov twj tso kua tshuaj txheem

- Cov twj tso kua helical ntsia hlau

- Cov twj tso kua mis

- Cov twj tso kua dej ncig

- Cov twj tso kua dej

- Cov twj tso dej thiab cov dej khib nyiab

s

Kev ua haujlwm ntau yam

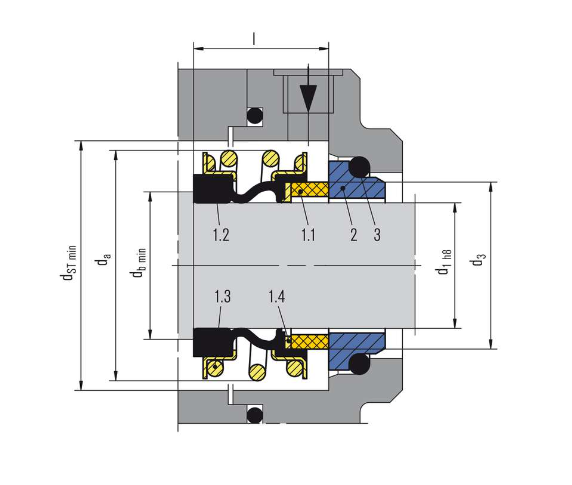

Txoj kab uas hla ntawm lub ncej:

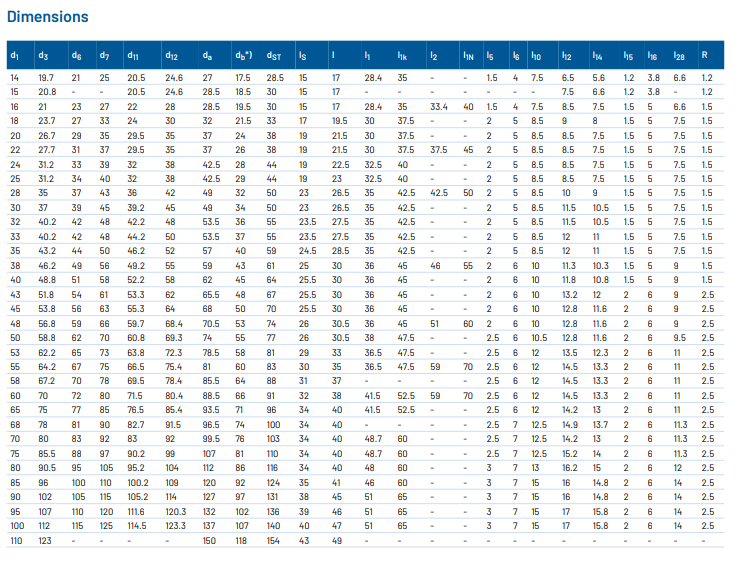

d1 = 14 … 110 hli (0.55″ … 4.33″)

Siab: p1 = 18 bar (261 PSI),

nqus tsev ... 0.5 bar (7.25 PSI),

txog li 1 bar (14.5 PSI) nrog lub rooj zaum xauv

Kub: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Qhov ceev ntawm kev swb: vg = 10 m/s (33 ft/s)

Kev txav mus los axial uas tso cai: ±2.0 hli (±0.08″)

Cov khoom siv sib xyaw ua ke

Nplhaib ruaj khov: Ceramic, Carbon, SIC, SSIC, TC

Lub Nplhaib Tig: Ceramic, Carbon, SIC, SSIC, TC

Secondary Seal: NBR/EPDM/Viton

Caij nplooj ntoos hlav thiab hlau qhov chaw: SS304/SS316

Daim ntawv qhia txog WeMG1 ntawm qhov ntev (hli)

Lub foob pob zeb rau kev lag luam marine