Peb txoj kev nrhiav thiab lub hom phiaj ntawm lub tuam txhab yog ib txwm "Ib txwm ua kom tau raws li peb cov neeg siv khoom xav tau". Peb pheej nrhiav thiab tsim thiab tsim cov khoom zoo tshaj plaws rau peb cov neeg siv khoom qub thiab tshiab thiab ncav cuag lub sijhawm yeej-yeej rau peb cov neeg siv khoom thiab peb rau H7N twj tso kua mis lub foob rau kev lag luam marine, Koj txoj kev taw qhia yog peb lub zog hluav taws xob mus ib txhis! Txais tos cov neeg siv khoom hauv koj lub tsev thiab txawv teb chaws tuaj rau peb lub tuam txhab.

Peb txoj kev nrhiav thiab lub hom phiaj ntawm lub tuam txhab yog ib txwm "Ib txwm ua kom tau raws li peb cov neeg siv khoom xav tau". Peb pheej nrhiav thiab tsim cov khoom zoo tshaj plaws rau txhua tus neeg siv khoom qub thiab tshiab thiab ua tiav qhov kev cia siab rau peb cov neeg siv khoom thiab peb rauLub Twj Tso Kua Mis Mechanical, Mechanical Seal thiab Twj Tso Kua Roj, Twj Tso Kua Mis Thiab Lub Rooj Sib Tham, Lub npe tuam txhab, yeej ib txwm saib xyuas qhov zoo ua lub hauv paus ntawm lub tuam txhab, nrhiav kev txhim kho los ntawm kev ntseeg siab, ua raws li ISO tus qauv kev tswj hwm zoo nruj me ntsis, tsim lub tuam txhab qeb siab tshaj plaws los ntawm kev ua siab ncaj thiab kev cia siab.

Cov yam ntxwv

• Rau cov kauj ruam

•Ib lub foob

•Sib npaug

•Super-Sinus-caij nplooj ntoos hlav lossis ntau lub caij nplooj ntoos hlav tig

•Ywj siab ntawm kev tig

• Muaj cov cuab yeej twj tso kua dej sib xyaw ua ke

• Muaj ntau hom uas muaj lub rooj zaum txias

Cov txiaj ntsig

•Cov cib fim rau kev thov thoob ntiaj teb (kev ua tus qauv)

• Kev khaws cia khoom zoo vim muaj cov ntsej muag sib pauv tau yooj yim

• Kev xaiv cov ntaub ntawv ntau ntxiv

• Kev yooj yim hauv kev sib kis torque

• Cov nyhuv ntxuav tus kheej

•Qhov ntev ntawm kev teeb tsa luv luv tau (G16)

Cov ntawv thov pom zoo

•Kev lag luam txheej txheem

•Kev lag luam roj thiab roj av

• Kev siv tshuab ua kom zoo dua qub

•Kev lag luam roj av

•Kev lag luam tshuaj lom neeg

• Kev siv tshuab fais fab

• Kev lag luam pulp thiab ntawv

•Kev lag luam khoom noj thiab dej haus

• Kev siv dej kub

• Cov roj hydrocarbon sib dua

•Cov twj tso kua mis Boiler

•Cov twj tso kua mis ua haujlwm

Kev ua haujlwm ntau yam

Txoj kab uas hla ntawm lub ncej:

d1 = 14 … 100 hli (0.55″ … 3.94″)

(Ib lub caij nplooj ntoos hlav: d1 = siab tshaj 100 hli (3.94″))

Siab:

p1 = 80 bar (1,160 PSI) rau d1 = 14 … 100 hli,

p1 = 25 bar (363 PSI) rau d1 = 100 … 200 hli,

p1 = 16 bar (232 PSI) rau d1 > 200 hli

Kub:

t = -50 °C … 220 °C (-58 °F … 428 °F)

Qhov ceev ntawm kev swb: vg = 20 m/s (66 ft/s)

Kev txav mus los ntawm axial:

d1 txog 22 hli: ± 1.0 hli

d1 24 txog 58 hli: ± 1.5 hli

d1 txij li 60 hli: ± 2.0 hli

Cov Khoom Siv Ua Ke

Lub ntsej muag tig

Silicon carbide (RBSIC)

Cov roj carbon graphite impregnated

Tungsten carbide

Hlau Cr-Ni-Mo (SUS316)

Rooj Zaum Nres

Silicon carbide (RBSIC)

Cov roj carbon graphite impregnated

Tungsten carbide

Kev Pabcuam Seal

Fluorocarbon-Roj Hmab (Viton)

Ethylene-Propylene-Diene (EPDM)

Silicone-Roj Hmab (MVQ)

PTFE Txheej VITON

Caij nplooj ntoos hlav

Hlau tsis xeb (SUS304)

Hlau tsis xeb (SUS316)

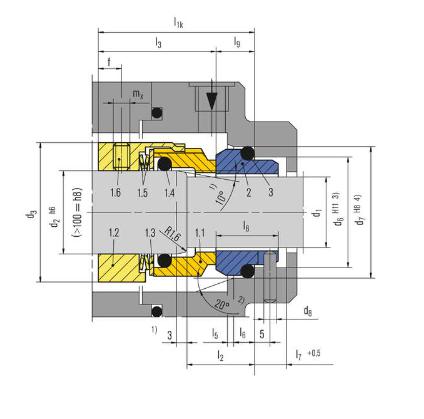

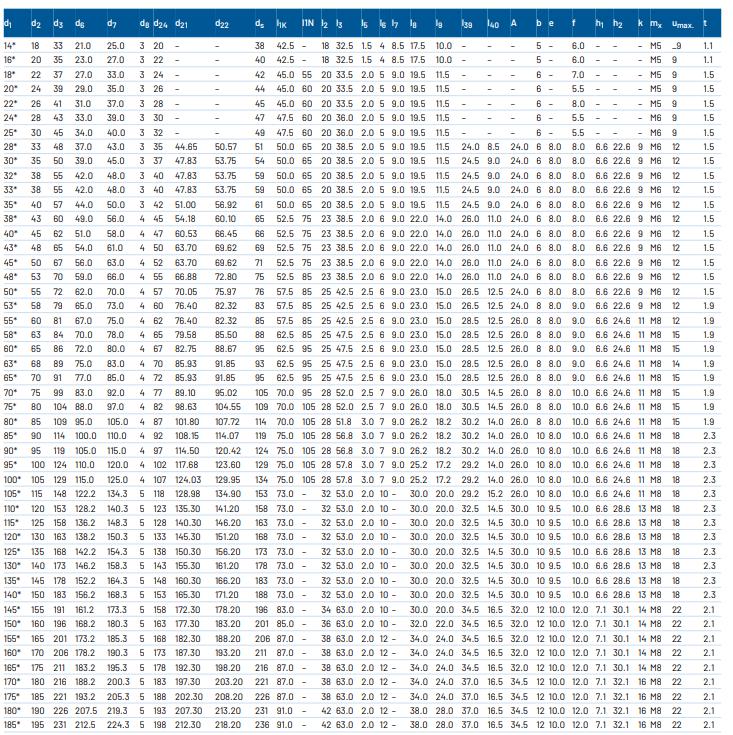

Daim ntawv qhia txog WH7N ntawm qhov ntev (hli)

WAVE SPRINGS YOG COMPACT BIDIRECTIONAL SEALS CHAWV TSIM LOS RAU KEV UA HAUJ LWM LUV NEEJ THIAB COV KEV YUAV TSUM TAU HUVSI.

Cov caij nplooj ntoos hlav nthwv dej yog cov khoom siv kho tshuab uas tsim los hloov cov caij nplooj ntoos hlav hlau puag ncig hauv cov ntawv thov uas xav tau cov lus qhia txog kev thauj khoom nruj hauv qhov chaw muaj teeb meem. Lawv muab lub ntsej muag thauj khoom sib npaug dua li Parallel lossis Taper Spring, thiab qhov yuav tsum tau ua kom me dua kom ua tiav lub ntsej muag thauj khoom zoo sib xws.

Cov foob pob hluav taws xob ob txoj kev muaj cov qauv tsim foob thiab cov thev naus laus zis nthwv dej, hauv ntau yam khoom siv sib xyaw. Qhov no tau txhim kho los ntawm cov yam ntxwv tsim zoo tshaj plaws, txhua yam ntawm cov nqi sib tw heev.

H7N twj tso kua mis lub foob, lub foob twj tso kua mis lub foob, lub foob twj tso kua mis ncej, twj tso kua mis thiab foob