Koj ua lub luag haujlwm tseem ceeb hauv kev txhawb nqa lub twj tso kua mis thaum koj xaiv txoj caitwj rotor set. Los ntawm kev xaiv ntse, koj tuaj yeem ua tiav3.87% kev ua haujlwm siab duathiab txaus siab rau lub sijhawm tu ncua ntev. Cov kev tshawb fawb tsis ntev los no qhia tau hais tias kev ua kom zoo tshaj plaws rotors tuaj yeem ua kom cov twj tso kua mis ntws los ntawm 25%, txhawb kev vam meej.

Ntsiab Cai

- Xaiv txoj cai twj tso kua mis rotor hom thiab tsim boosts efficiency, txaus, thiab twj tso kua mis lifespan nyob rau hauv ntau yam kev siv.

- Xaiv cov ntaub ntawv tsim nyog thiab cov txheej txheem qib siab txhim kho rotor durability, txo kev txij nkawm, thiab txuag nqi.

- Kev tshuaj xyuas tsis tu ncua thiab kev xaiv rotor ntse pab kom tsis txhob muaj kev puas tsuaj, txiav kev siv lub zog, thiab ua kom lub twj tso kua mis ua tau zoo.

Yuav ua li cas Pump Rotors ua hauj lwm nyob rau hauv ntau yam twj tso kua mis

Centrifugal Pump Rotors

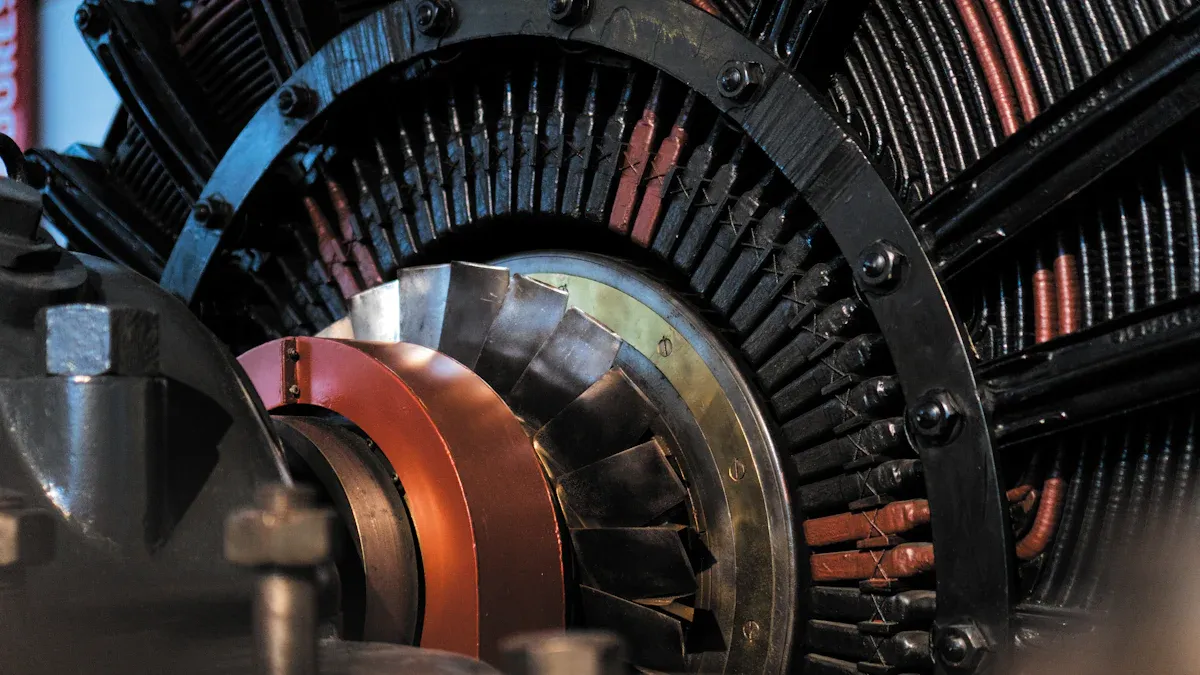

Koj tuaj yeem qhib lub zog tiag tiag ntawm cov dej txav nrog centrifugaltwj rotors. Cov rotors no, feem ntau hu ua impellers, tig nrawm los tsim kom muaj lub zog muaj zog uas thawb cov kua tawm sab nraud ntawm qhov chaw. Qhov kev txiav txim no hloov lub zog txhua yam los ntawm lub cev muaj zog mus rau lub zog kinetic, txav dej los yog lwm yam dej los ntawm lub twj tso kua mis thiab rau hauv koj lub cev.

Thaum koj xaiv lub twj tso kua mis centrifugal, koj koom nrog feem ntau ntawm kev lag luam thoob ntiaj teb. Qhov tseeb, cov twj centrifugal tuav ib qho loj heev65% sib koomntawm kev lag luam twj tso kua mis hauv xyoo 2021. Koj pom lawv nyob txhua qhov chaw - los ntawm cov chaw kho dej mus rau cov chaw tsim tshuaj lom neeg - vim tias lawv tuav ntau cov kua dej thiab cov nqi ntws.

Tswv yim:Xaiv txoj cai impeller tsim tuaj yeem txhawb koj lub twj tso kua mis kev ua haujlwm thiab kev ntseeg tau.

Kev ua tau zoo sib txawv raws li cov kua dej thiab lub twj tso kua mis geometry. Piv txwv li, kev sim qhia tau hais tias qee cov twj centrifugal ua tiav a3.3% siab dua lub taub haunrog qee qhov kev daws teeb meem piv rau dej. Txawm li cas los xij, txo qhov ceev ntawm lub rotor ua rau pom kev poob qis hauv kev ua haujlwm. Cov lej simulations paub meej tias cov kev tshawb pom no, qhia tias cov twj tso kua mis axial tuaj yeem ncav cuag qhov ua tau zoo li siab.86.3%, thaum lwm cov qauv tsim yuav poob qis dua 80%. Cov kev sib txawv no tseem ceeb thaum koj xav ua kom cov zis ntau tshaj plaws thiab txo qis kev siv zog.

Ntawm no yog saib ceev ceev ntawm cov centrifugal twj rotor specifications:

| Specification / Parameter | Nqe lus piav qhia / Tus nqi |

|---|---|

| Daim Ntawv Qhia Txog Qhov Ntsuas | U = 4W / N (U hauv oz-in, W = bearing journal static weight, N = max service speed) |

| Qib ISO | Txog 0.7 (ISO 1940-1) |

| API 610 Kev Ntsuas Ntsuas | Dynamic ntsuas rau ISO 1940-1 Qib 2.5 lossis zoo dua |

| Qhov tseem ceeb ntawm Kev Ntsuas | Txo kev vibration, nce bearing lub neej, thiab txiav downtime |

Koj tuaj yeem pom tias kev sib npaug thiab kev xaiv tsim pab koj ua tiav kev ua haujlwm zoo dua thiab ua haujlwm ntev dua. Thaum koj nqis peev rau hauv txoj cai centrifugal twj rotor, koj teeb tsa koj tus kheej kom ua tiav hauv txhua daim ntawv thov.

Positive Displacement Pump Rotors

Koj tuaj yeem suav rau qhov zoo ntawm cov twj tso kua mis hloov chaw thaum koj xav tau khov kho, txhim khu kev qha - txawm tias cov kua dej tuab lossis nplaum. Cov rotors no ntxiab cov kua dej tas li thiab txav mus los ntawm lub twj tso kua mis nrog txhua qhov kev sib hloov. Qhov kev tsim no muab kev tswj xyuas meej meej rau koj, ua cov twj no zoo tagnrho rau kev lag luam xws li zaub mov, tshuaj, thiab roj & roj.

Koj muaj ntau tus qauv rotor xaiv los ntawm, txhua tus muaj lub zog tshwj xeeb:

| Hom twj tso kua mis | Rotor Design Yam ntxwv | Kev Pom Kev Ua Tau Zoo Raws li kev tsim thiab kev thov kom haum |

|---|---|---|

| Circumferential Piston | Rotors tsis kov lossis mesh; foob tsim ntawm stators thiab rotors | Superior efficiency ntawm tsawg viscosity; kim dua |

| Lobe | Rotors nyob ze-kev sib cuag; ntau lobe configuration | Zoo heev rau cov khoom tuab; tsawg dua ntawm viscosity tsawg |

| Twin-Screw | Ob spindles hloov khoom axially; qis pulsation | Yooj yim tuav, hnav tsis tshua muaj, tus nqi siab dua |

Cov kev sim kuaj pom tau hais tias cov twj tso kua mis ncig lub piston ci nrog cov kua dej uas tsis muaj viscosity, thaum lub lobe thiab ntxaib-ntsia hlau tsim tau zoo nrog cov ntaub ntawv tuab. Koj tuaj yeem pom cov twj tso kua mis no hauv kev nqis tes ua thoob plaws ntau qhov kev lag luam, los ntawm kev txav cov qhob noom xim kasfes hauv lub Hoobkas khoom qab zib mus rau kev tuav cov roj crude hauv lub refinery.

Kev sim cov kev tshawb fawb ntawm cov cua-tsav piston twj tso kua mis qhia tau hais tias ntxiv cov accumulators siab tuaj yeem txo qhov siab nce mus txog.68%. Qhov no txhais tau tias kev ua haujlwm smoother thiab hnav tsawg dua ntawm koj cov khoom siv. Thaum koj xaiv txoj cai zoo hloov chaw rotor, koj tau txais kev tswj, kev ua tau zoo, thiab kev thaj yeeb ntawm lub siab.

Progressive Cavity Pump Rotors

Koj tuaj yeem ua tiav cov txiaj ntsig zoo kawg nkaus nrog cov kab noj hniav zoo nkauj rotors, tshwj xeeb tshaj yog thaum koj ntsib cov kua dej sib tw lossis xav tau maj mam, zoo ib yam. Cov rotors no muaj qhov tshwj xeeb helical zoo uas txav cov kua dej los ntawm cov kab noj me me, kaw cov kab noj hniav. Qhov kev tsim no tswj txhua yam ntawm cov dej khib nyiab mus rau cov slurries tuab nrog yooj yim.

Nco tseg:Progressive kab noj hniav twj tso kua mis yog koj mus-rau kev daws rau daim ntaub ntawv uas lwm yam twj tso kua mis tawm tsam.

Kev tsim kho tshiab tsis ntev los no tau ua rau cov rotors no zoo dua. Piv txwv li, Vogelsang HiCone tsim tso cai rau koj kho lub rotor txoj hauj lwm, rov qab compression qub thiab ncua lub neej ntawm ob qho tib si rotor thiab stator mus txog rau.plaub zaug. Koj tuaj yeem ua cov kev hloov pauv no manually lossis txiav, ua kom koj lub twj tso kua mis khiav zoo li tshiab thiab txo qis sijhawm.

Ntawm no yog qhov ua tau zoo ntawm cov kab noj hniav rotors txhim kho kev ua haujlwm:

| Numerical Data Aspect | Nqe lus piav qhia / Cov txiaj ntsig |

|---|---|

| Qhov hluav taws xob siab | Cov qauv tsim tshiab ua tiavsiab dua qhov hluav taws xobdua li cov qauv qub. |

| Axial Leakage Ceev | Txhim kho cov qauv qhia pom tsis tshua muaj paug, txhawb kev ua haujlwm zoo. |

| Internal Compression txheej txheem | Tshwj xeeb compression ua rau kom tso tawm siab thiab txhim kho cov dej txav. |

Koj tau txais txiaj ntsig los ntawm kev siv hluav taws xob qis dua, lub sijhawm ua haujlwm ntev dua, thiab txo nqi txij nkawm. Los ntawm kev xaiv lub tshuab nqus tsev twj tso kua mis rotor, koj txhawb koj lub zog los daws cov haujlwm nyuaj nrog kev ntseeg siab thiab ua haujlwm zoo.

Pump Rotor Set: Khoom siv, tsim, thiab xaiv

Cov khoom siv rotor

Koj tuaj yeem qhib cov qib tshiab ntawm kev ua tau zoo los ntawm kev xaiv cov ntaub ntawv zoo rau koj lub twj tso kua mis rotor teeb. Txhua yam khoom coj los ua lub zog tshwj xeeb, thiab koj qhov kev xaiv tsim lub twj tso kua mis durability, efficiency, thiab nqi. Rau cov dej huv, koj feem ntau pomrotors ua los ntawm cam khwb cia hlau, txhuas, bronze, stainless hlau, los yog polymer. Yog tias koj lis dej turbid, polymers yuav tsis yog qhov kev xaiv zoo tshaj plaws. Thaum koj txav dej nrog cov khib nyiab, aluminium tsis haum. Rau dej kub, hlau, tooj dag, thiab stainless hlau ci. Hauv dej hiav txwv, bronze lossis stainless hlau sawv tawm, thaum cam khwb cia hlau poob luv. Lub pas dej da dej thiab lub pas dej da dej xav tau cov khoom siv polymer los tiv thaiv cov tshuaj chlorine cov teebmeem hnyav.

Advanced ntaub ntawv zoo lihybrid compositestab tom hloov qhov kev ua si. Tam sim no koj tuaj yeem ua ke cov hlau thiab cov polymers los txhawb cov kav ntev thiab txo kev sib txhuam. Cov txheej txheem tiv thaiv xws li tungsten carbide, siv los ntawm thermal spraying lossis tshuaj vapor deposition, ua rau koj lub twj tso kua mis rotor teeb nruj dua tiv thaiv kev puas tsuaj thiab corrosion. Cov kev tsim kho tshiab no pab koj khiav twj tso kua mis ntev dua, txawm tias nyob hauv ib puag ncig hnyav.

Tswv yim:Kev xaiv cov khoom siv zoo tuaj yeem txuas koj lub twj tso kua mis lub neej thiab txiav cov nqi tu.

Kev tshawb fawb txheeb cais qhiaE-iav fiber ntau yog qhov kev lag luam tshaj plaws thiab siv davhauv rotor composites. Cov pa roj carbon fibers muab koj lub zog ntau dua thiab nruj, tshwj xeeb tshaj yog thaum qaug zog yog ib qho kev txhawj xeeb, tab sis lawv raug nqi ntau dua thiab tuaj yeem corrode. Aramid fibers muaj zog toughness thiab cuam tshuam tsis kam, txawm tias lawv tsis muaj zog hauv compression. Hybrid composites cia koj sib npaug tus nqi, lub zog, thiab kav ntev. Cov ntaub ntawv qaug zog qhia txog qhov xav tau rau kev tsim khoom zoo thiab kev sim mus sij hawm ntev kom ntseeg tau tias koj lub twj tso kua mis rotor teeb nyob ruaj khov.

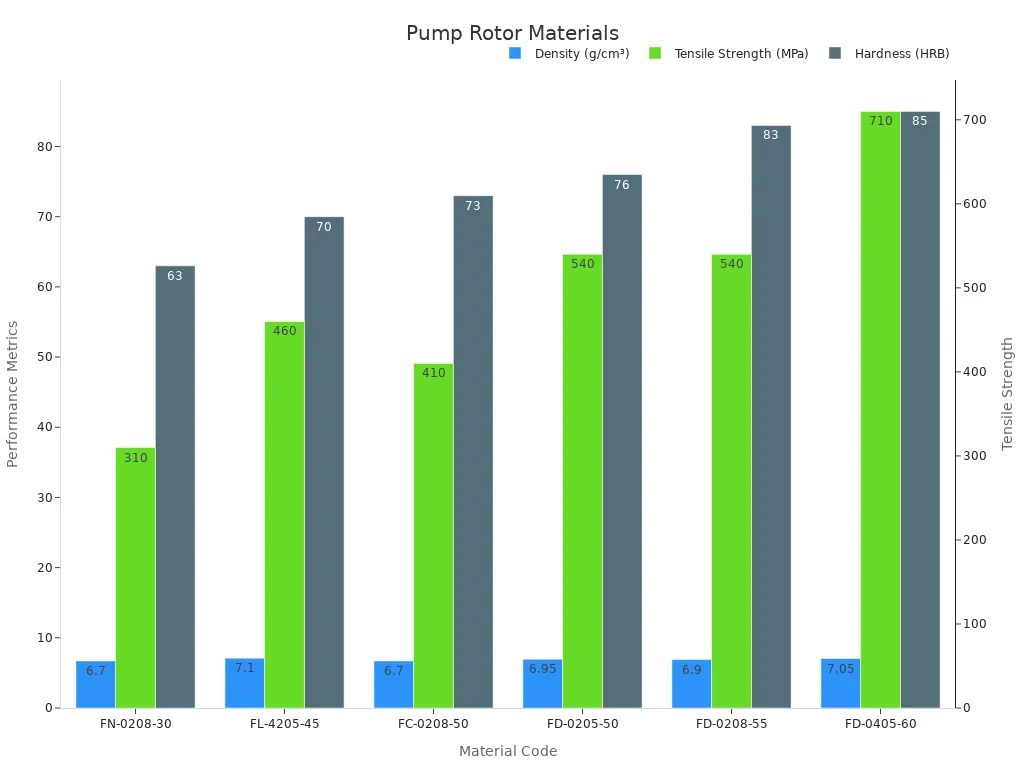

Koj tuaj yeem pom qhov sib txawv hauvcov khoom ua tau zoo nyob rau hauv cov lus hauv qab no:

| Khoom siv Code | Qhov ceev (g / cm³) | Tensile zog (MPa) | Hardness (HRB) |

|---|---|---|---|

| FN-0208-30 | 6.70 ib | 310 | 63 |

| FL-4205-45 | 7.10 Nws | 460 | 70 |

| FC-0208-50 | 6.70 ib | 410 | 73 |

| FD-0205-50 | 6.95 ib | 540 | 76 |

| FD-0208-55 | 6.90 ib | 540 | 83 |

| FD-0405-60 | 7.05 Nws | 7 10 | 85 |

Koj tuaj yeem sib piv cov khoom no visually:

Tsis ntev los no cov kev ntsuam xyuas durability ntawm graphite rotors qhia tau tiasKev xaiv cov khoom siv cuam tshuam ntev npaum li cas koj lub twj tso kua mis rotor teeb kav ntev. Piv txwv li, ib hom graphite rotor poob tsuas yog 36.9% ntawm nws cov khoom tom qab tshaj 1,100 cycles thiab ua haujlwm, thaum lwm tus ua tsis tau sai dua. Qhov no ua pov thawj tias koj qhov kev txiav txim siab ntawm cov khoom siv ncaj qha cuam tshuam rau kev ntseeg siab ntawm lub twj tso kua mis.

Rotor Design Features

Koj tuaj yeem ua tiav qhov ua tau zoo thiab kev ntseeg tau zoo los ntawm kev tsom mus rau cov qauv tsim ntawm koj lub twj tso kua mis rotor teeb. Niaj hnub nimno engineering coj koj cov kev kho saum npoo zoo lithermal spray txheej thiab tshuaj vapor deposition. Cov txheej txheem no txo kev sib txhuam thiab hnav, ua rau koj cov rotors kav ntev dua thiab ua haujlwm zoo dua.

Koj tau txais txiaj ntsig los ntawm precision-engineered lubricants nrog tshwj xeeb additives. Cov no ua kom txav qhov chaw sib cais, qis kev sib txhuam, thiab txuas ntxiv lub neej ntawm koj lub twj tso kua mis rotor teeb. Cov cuab yeej suav xws li Finite Element Analysis (FEA) thiab Computational Fluid Dynamics (CFD) pab koj txhim kho rotor geometry thiab ntws txoj hauv kev. Qhov no txhais tau hais tias tsawg zog nkim thiab cov kua dej ntau dua nrog txhua qhov kev sib hloov.

- Tight manufacturing tolerances txo backflow thiab to, boosting efficiency.

- Laser alignment systems xyuas kom koj cov ncej tig zoo kawg nkaus, tiv thaiv kev ntxhov siab thiab ua tsis tiav thaum ntxov.

- Rotor thiab chamber tsim tsim du, ruaj khov, uas yog qhov zoo tagnrho rau cov kua dej rhiab lossis tuab.

- Real-time sensors thiab tshuab kev kawm kwv yees xav tau kev saib xyuas, txiav downtime thiab txuag nyiaj.

Nco tseg:Kev ua haujlwm qis hauv cov twj rotor tuaj yeem txuag koj txog 30% hauv lub zog thiab txuas ntxiv lub neej ntawm 20-25%.

Lub rotor geometry tshiab kuj muab kev txhim kho ntsuas tau. Piv txwv li,optimizing hniav suab thiab soliditytxhim kho flowmeter raug. Kho qhov sib piv ntawm hub-rau-ntsis thiab cov kaum sab xis txo qhov ua yuam kev thiab ua kom qhov kev ua tau zoo. Siv genetic algorithms los ua kom zoo dua cov duab ntawm lub kiv cua tau txiav qhov tsis yog-linearity yuam kev los ntawm ib nrab thiab txo qis qhov ntsuas qhov nrawm nrawm. Cov kev tsim kho tshiab no pab koj tau txais ntau tshaj plaws los ntawm koj lub twj tso kua mis rotor teeb.

Kev simulation thiab kev sim ua qauv paub meej tias cov txiaj ntsig no. Piv txwv li, ib tug ntxaib-rotor tsim ua tiav aLub zog coefficient siab dua 0.44thiab txhim kho lub zog hloov dua siab tshiab los ntawm 9% dua li cov qauv tsim. Cov txiaj ntsig no qhia tau tias kev xaiv tsim qauv ntse ua rau muaj txiaj ntsig hauv ntiaj teb tiag.

Xaiv Txoj Cai Pump Rotor Teeb

Koj tuav lub zog los hloov koj qhov kev ua tau zoo los ntawm kev xaiv lub twj tso kua mis rotor teeb. Pib los ntawm kev xav txog kev ua haujlwm thiab kev siv hluav taws xob. Cov txheej txheem ua haujlwm siab tuaj yeem txo koj cov nqi khiav lag luam thiab kev cuam tshuam ib puag ncig. Piv txwv li, mus tas li hlau nplaum lub cev muaj zog twj tso kua mis rotor teev ncav cuagmus txog 94% efficiency-10-12 feem pua cov ntsiab lus siab dua cov qauv motors. Qhov no tuaj yeem txuag koj txog 21% hauv kev siv hluav taws xob thiab txiav CO2 emissions txhua xyoo los ntawm ntau dua 32 tons hauv qee daim ntawv thov.

Thaum koj xaiv lub twj tso kua mis rotor teeb, saib cov qauv tseem ceeb no:

- Efficiency thiab kev txuag hluav taws xob

- Flow tswj adaptability rau kev hloov kev xav tau

- Durability thiab hnav tsis kam rau lub neej ntev

- Tsis tshua muaj suab nrov rau qhov chaw ua haujlwm muaj kev nyab xeeb, xis nyob dua

- Compact tsim thiab yooj yim installation

Koj kuj yuav tsum tauua haujlwm koj lub twj tso kua mis siab tshaj 60% ntawm nws qhov Kev Ua Haujlwm Zoo Tshaj Plaws (BEP)kom tsis txhob muaj kev vibration thiab instability. Khaws rotor deflection qis los tiv thaiv cov ntsaws ruaj ruaj thiab tiv thaiv kev puas tsuaj. Lub twj tso kua mis muaj zog thiab cov qauv hauv qab ua rau txo qis kev sib raug zoo thiab kev ntxhov siab. Saib rau cov teebmeem dynamic zoo li resonance, tshwj xeeb nrog cov twj tso kua mis ceev. Tsis tu ncua xyuas rau hnav, raws li kev tshem tawm ntau tuaj yeem txo qis kev ua haujlwm. Kev txhim kho zoo-cov hauv paus ruaj khov, kev sib raug zoo, thiab cov kav dej tsawg tsawg-pab koj lub twj tso kua mis rotor teeb ua qhov zoo tshaj plaws.

Kev tshoov siab:Txhua qhov kev xaiv ntse koj xaiv thiab tswj xyuas koj lub twj tso kua mis rotor teeb coj koj los ze zog rau qhov ua tau zoo thiab kev vam meej.

Cov ntaub ntawv tshawb fawb ua pov thawj tus nqi ntawm koj cov peev txheej. Hauv kev lag luam mining, hloov mus rau lub twj tso kua mis rotor muaj peev xwm txuag tau ze li ntawm 42,000 kWh ntawm lub zog txhua xyoo thiab them rau nws tus kheej hauv tsawg dua ob xyoos. Hauv cov nroog hauv nroog, cov kev hloov kho tshiab no sib npaug ntawm kev txuag hluav taws xob ntawm kev hloov dua 300 qhov muag teeb nrog LEDs. Koj tuaj yeem ua tiav cov txiaj ntsig zoo sib xws los ntawm kev tsom mus rau txoj cai twj tso kua mis rotor teem rau koj cov kev xav tau.

Koj tsav twj tso kua mis ua tiav los ntawm kev xaiv lub rotor txoj cai thiab ua kom nws nyob rau hauv cov duab saum toj kawg nkaus.

- Kev tshuaj xyuas tsis tu ncua nrog cov ntaub ntawv ntse pab koj pom cov teeb meem ntxov thiab tsis txhob muaj kev puas tsuaj.

- Ceev fajxaiv rotorboosts efficiency thiab txuag nyiaj thaum lub sij hawm.

- Cov txiaj ntsig me me hauv kev ua haujlwmtuaj yeem ua rau muaj kev txuag nyiaj loj thiab tsis muaj sijhawm poob.

FAQ

Yuav ua li cas yog tias koj tsis quav ntsej rotor tu?

Koj pheej hmoo lub twj tso kua mis tsis ua haujlwm thiab kev kho nqi kim. Kev kuaj xyuas tsis tu ncua ua kom koj lub cev muaj zog thiab txhim khu kev qha. Nyob twj ywm thiab saib koj lub twj tso kua mis vam meej.

Koj paub li cas thaum hloov lub twj tso kua mis rotor?

Koj pom cov suab txawv txawv, qis qis, lossis xau. Cia siab rau koj txoj kev xav. Kev ua sai sai pab koj kom tsis txhob muaj teeb meem loj dua thiab ua kom koj lub twj tso kua mis ua haujlwm zoo.

Koj puas tuaj yeem hloov kho koj lub twj tso kua mis rotor kom ua tau zoo dua?

kiag li! Koj tuaj yeem xaiv cov khoom siv qib siab lossis cov qauv tsim tshiab. Kev kho dua tshiab boosts efficiency thiab ncua koj lub twj tso kua mis lub neej. Txhua qhov kev txhim kho coj koj los ze zog rau kev vam meej.

Lub sij hawm xa tuaj: Plaub Hlis-09-2025